Lahore is Pakistan’s vibrant textile and fashion manufacturing hub. Known for its rich garment export ecosystem, the city is also witnessing a growing demand for hosiery packaging—both for local sales and international exports. Whether you operate a socks factory in Shahdara, a retail brand in Gulberg, or a knitwear business in Kot Lakhpat, understanding the real cost of packaging hosiery items is vital to maintain profit margins and meet buyer expectations.

But hosiery packaging costs in Lahore aren’t fixed. They depend on a variety of factors—material, design, volume, compliance, and even your packaging partner.

This article explores current pricing trends, hidden costs, and value-driven recommendations. Plus, we’ll look at regional insights, packaging innovations supported by STZA and Ignite, and what textile businesses in South Punjab can learn from Lahore’s evolving packaging ecosystem.

Hosiery Packaging Price Range in Lahore (2025)

Quick Answer: Packaging for hosiery items in Lahore typically ranges from PKR 6 to PKR 60 per unit, depending on customization, volume, and material.

The cost spectrum reflects differences in both product type and packaging sophistication. For example, a basic pair of cotton socks may require minimal kraft paper banding, while luxury tights demand box inserts, UV-print sleeves, and eco-certifications.

Average Cost Examples:

-

Paper belly band (basic): PKR 6–10 per unit

-

Printed hang tag + polybag: PKR 12–20 per unit

-

Box packaging with window: PKR 30–45 per unit

-

Custom eco-friendly box set: PKR 50–60 per unit

💡 Tip from Lahore: Factories in Sundar Industrial Estate report better unit prices when ordering in 20,000+ quantities and using locally recycled materials.

Factors Affecting Hosiery Packaging Cost in Pakistan

Quick Answer: Material, printing, customization, volume, and certifications directly impact pricing.

If you’re a Lahore-based hosiery exporter, your packaging partner will likely evaluate the following before quoting:

-

Material Type – Kraft, cardboard, biodegradable film, or clear PET

-

Print Style – Offset, flexo, UV coating, embossing

-

Design Complexity – Die-cut, window, foldable box, zip-lock sleeves

-

Quantity Ordered – Larger batches = lower cost per unit

-

Certifications Needed – FSC, ISO, plastic-free labels

🎯 Example: A knitwear company in Township Lahore reduced packaging cost by 18% by switching from imported boxes to FSC-certified Pakistani paperboard.

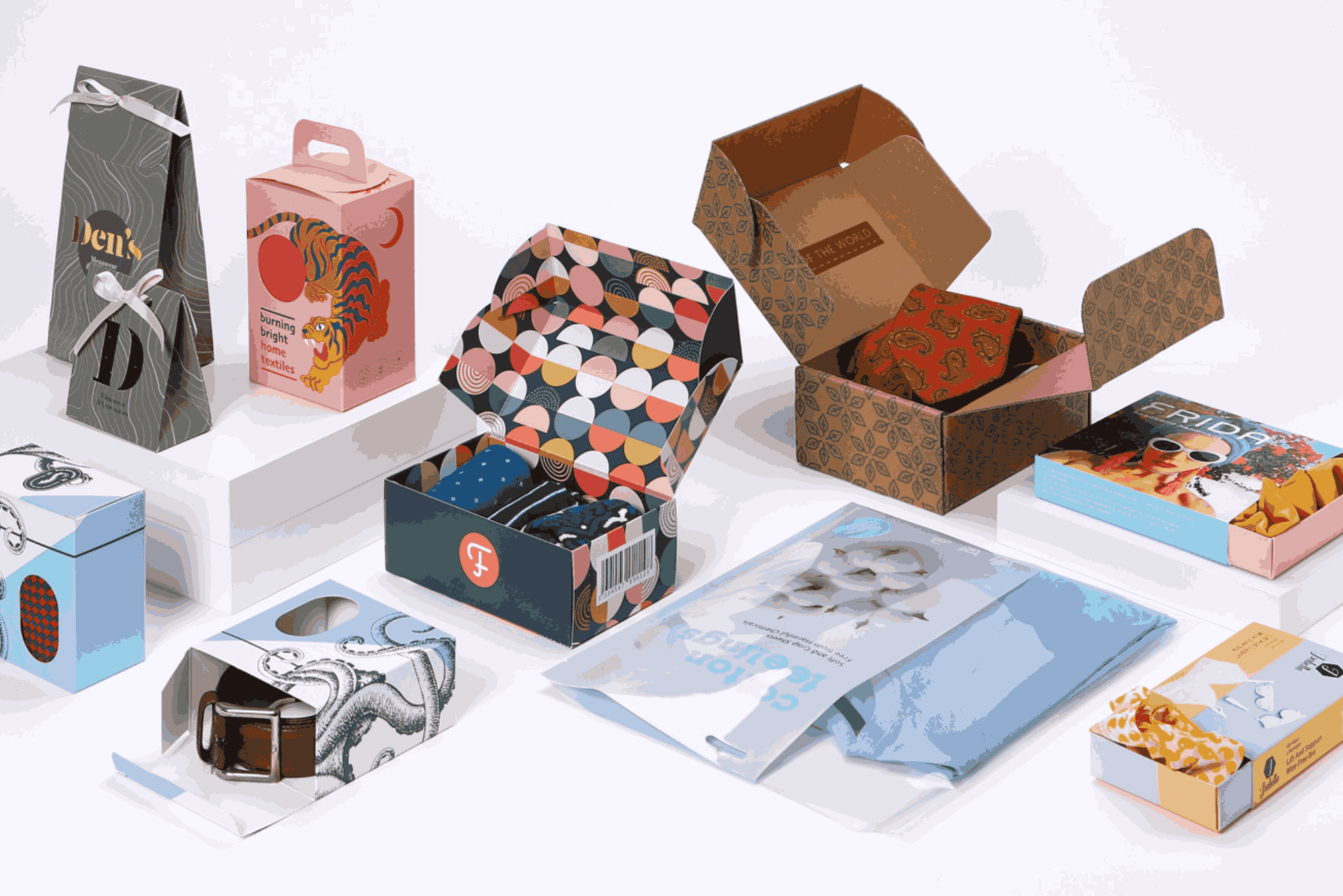

Custom vs Standard Hosiery Packaging Options

Quick Answer: Standard packaging is cheaper upfront; custom designs provide branding advantages and export compliance.

While many SMEs in Lahore use standard hang tags or polybags, high-growth brands and exporters increasingly invest in custom packaging to stand out.

Standard Packaging Features:

-

Ready-made templates

-

Low MOQ (Minimum Order Quantity)

-

Lower costs

-

Limited design freedom

Custom Packaging Features:

-

Tailored size, material, finish

-

Better fit for brand identity

-

Can include QR codes, buyer logos

-

Higher MOQ but scalable

📦 Pro Tip: Start with semi-custom designs to balance cost and branding. Lahore’s Bund Road industrial zone has suppliers offering low-MOQ custom print solutions.

Lahore vs South Punjab Hosiery Packaging Prices

Quick Answer: Lahore’s rates are 10–25% higher due to quality, design diversity, and proximity to packaging clusters.

While Lahore offers premium packaging infrastructure and faster prototyping, South Punjab—especially Multan, Vehari, and Bahawalpur—offers cost-effective solutions for basic and bulk packaging needs.

| Region | Avg Price (per unit) | Lead Time | Design Capabilities |

|---|---|---|---|

| Lahore | PKR 15–60 | 3–7 days | High |

| Multan | PKR 8–40 | 5–10 days | Moderate |

| Bahawalpur | PKR 6–25 | 7–12 days | Basic |

🧠 Ignite Initiative: Textile businesses in Dera Ghazi Khan received packaging grants in 2024 under Ignite’s SME Innovation Support Program to upgrade packaging quality for export competitiveness.

Midpoint Anchor Text Placement

To streamline your hosiery export workflow and meet rising buyer expectations, consider partnering with experts like Buddy Packaging. Their Lahore-ready hosiery packaging solutions are designed to support both startup manufacturers and export-scale enterprises—offering competitive pricing, fast turnaround, and eco-compliant materials tailored for Pakistan’s diverse textile markets.

Eco-Friendly Hosiery Packaging Cost in Lahore

Quick Answer: Eco-friendly packaging costs 15–30% more but improves brand perception and export viability.

With Europe and GCC buyers enforcing sustainability mandates, Pakistani exporters must adapt. In Lahore, several packaging vendors now offer:

-

FSC-certified kraft paper wraps

-

Biodegradable cornstarch bags

-

Soy ink printing

-

Recyclable mono-material boxes

Cost Impact:

-

Adds PKR 3–12 per unit vs standard materials

-

Avoids future fines or order rejection due to non-compliance

-

Enhances brand image on global platforms

💬 Expert Quote:

“Eco-packaging isn’t a luxury anymore—it’s a gateway to premium buyers and long-term contracts.”

— CEO, Ignite Pakistan, 2025 Green Exports Summit

Hidden Costs in Hosiery Packaging

Quick Answer: Tooling, setup, delivery, and quality inspection fees often go unnoticed.

Many Lahore-based businesses focus only on the per-unit quote. However, total packaging costs include:

-

Die-cut mold charges for custom boxes (PKR 5,000–15,000 one-time)

-

Plate charges for offset printing (PKR 3,000–10,000 per color)

-

Transport/delivery fees (especially to areas like Kot Lakhpat, Sheikhupura, or Kasur)

-

Wastage buffer (2–5% packaging loss)

📉 Case Study: A hosiery brand in Johar Town avoided a 10% overage by negotiating a flat-rate delivery and storage inclusion in their packaging agreement.

MOQ and Lead Time for Hosiery Packaging in Lahore

Quick Answer: Most vendors require 5,000–10,000 units minimum with lead times of 4–10 working days.

While Lahore packaging firms are known for their speed and quality, they often have volume constraints. For new businesses or seasonal sellers, that can create budget and timeline issues.

Suggested Approach:

-

Start with neutral standard templates (shorter lead time)

-

Book custom runs during off-peak months (Feb–Apr, Aug–Oct)

-

Partner with firms that offer “sample packs” or shared MOQ slots

📦 Vendor Tip: Vendors in Ichhra and Model Town Extension often collaborate with small hosiery startups on shared orders to meet MOQs cost-effectively.

People Also Ask

Q1: What is the minimum packaging cost per hosiery unit in Lahore?

As low as PKR 6 for basic belly bands; custom eco boxes may go up to PKR 60.

Q2: Are eco-friendly packaging options available in Lahore?

Yes, many vendors offer recyclable, biodegradable, and FSC-certified materials.

Q3: Does custom packaging cost more in Lahore?

Yes, but it offers better branding, buyer appeal, and export compliance.

Q4: Can I order packaging in small quantities in Lahore?

Most suppliers have 5,000+ MOQs, but some offer flexible runs for startups.

Q5: How does Lahore compare with South Punjab for hosiery packaging?

Lahore offers faster and more diverse packaging options, but costs are 10–25% higher.

Q6: What hidden charges should I expect when ordering packaging?

Plate setup, die-cutting, delivery fees, and wastage buffers are common.

Q7: How long does it take to get hosiery packaging delivered in Lahore?

Standard orders take 4–7 working days; custom orders may need 10+ days.

Final Thoughts

Having advised dozens of textile businesses in Multan, Khanewal, and Rahim Yar Khan, I’ve seen how strategic use of Lahore’s packaging ecosystem can transform small hosiery brands into export-ready operations.

The city offers unmatched diversity in materials, design services, and turnaround time. However, to avoid overspending, businesses must:

-

Understand per-unit vs total landed cost

-

Prioritize sustainable materials for long-term compliance

-

Leverage programs from STZA and Ignite to reduce tech and logistics costs

With rising demand for premium, sustainable, and compliant hosiery products, the cost of packaging in Lahore is not just a line item—it’s a long-term investment.